Design and manufacture bespoke hydraulic manifold blocks

We are here to help and give you solutions !

Providing constant support throughout your project. VMF Hydraulics will handle every step of your hydraulic manifold block project.

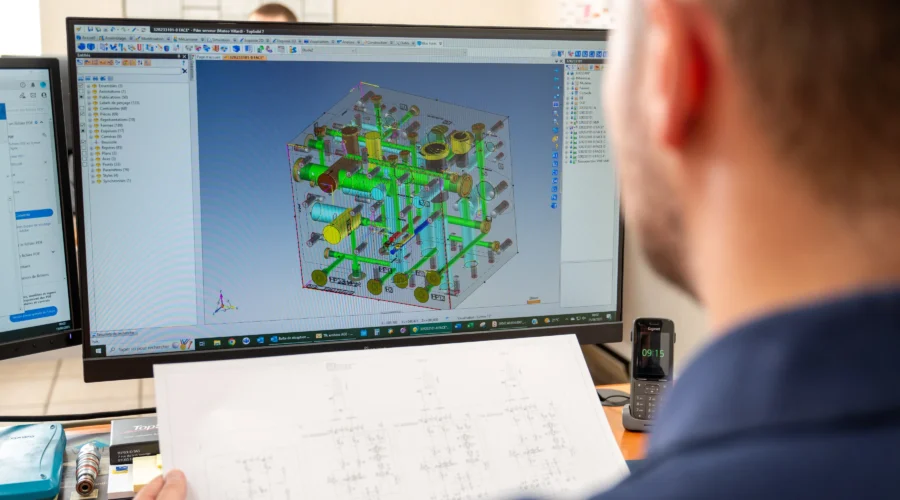

Design

We have an in-house design team. Our employees will endeavour to meet your technical and environmental criteria to tailor the product to your specification.

All the design work is performed in house. We work with the CAD/CAM software “TopSolid” to help us meet our clients’ expectations. A specific feature has been designed for us and by us alongside TopSolid’s developers team. This unique functionality is a powerful tool that supports us throughout the manufacturing process.

We look into the design internally to ensure the best possible hydraulic manifold block manufacturing process. We are able to start the process directly using our clients’ drawings.

VMF Hydraulics engineering supporting hydraulic manifold blocks design :

- Thorough assessment of the needs.

- Creation of the technical specification.

- Computer Assisted Design and Manufacture.

- Making the manufacturing steps reliable.

Manufacture

VMF Hydraulics manufacturing plant is composed of 19 machines and a full set of tools to create specific chambers and complex inclined drilling.

We own 11 CNC machines and 2 Fastems robot-linked Kitamura machines allowing us to manufacture manifold blocks 24/7. We have invested in the FPT’s Castel Terus 180 in order to make blocks weighing up to 10T and being 2+ metres long. On top of this, we have 10,000+ tools including 500 different shapes and 5,000 drill bits from 0.8mm to 80mm diameter. We also kept more traditional machines that would be more relevant to some specific types of manufacturing.

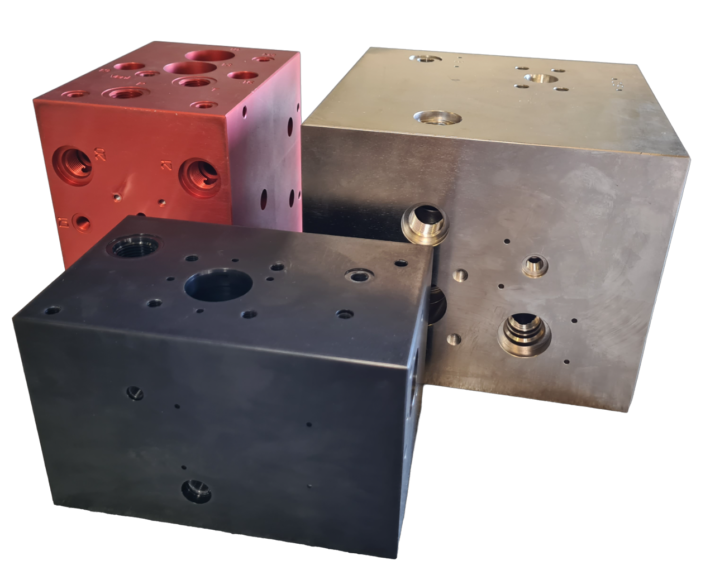

We offer and advise on a wide range of materials (steel, aluminium, cast iron, stainless steel) and surface treatment (galvanising, phosphating, anodizing, chemical nickel plating) at competitive costs. Such flexibility allows us to design hydraulic manifold blocks that meet all types of use within different environments.

Our expertise in manufacturing bespoke and reliable hydraulic manifold blocks :

- Wide range of machines and tools.

- 24/7 manufacturing capacity.

- A renowned expertise in large sized blocks.

- Wide range of materials and finishes.

Quality Control

Quality control and packaging are being carefully performed. We have a dedicated space for the finalising, control and packaging of our products to ensure we deliver the best possible quality.

Ultrasound, dimension, tapping and surface checks.. We thoroughly check our blocks prior to delivery :

- All bores are double checked using optic fibre

- Diameters and cavity checks

- Threadings checks

- Connections checks

- Surface quality checks to ensure a perfect sealing

Support

Rooted in the Lyon region since 1987, VMF Hydraulics has developed its expertise and know-how to meet all its clients needs.

Our teams will support your hydraulic manifold block projects in the long term.

Whether you need to relaunch hydraulic manifolds previously manufactured or tweak an existing system, VMF Hydraulics will be a long term partner. Our clients’ drawings are scanned and safely archived, allowing us to deal with queries with great responsiveness with a tailored approach.

At VMF Hydraulics, we support you in the long term :

- Responsiveness to previously designed blocks manufacturing

- Creation of a stock for recurring orders

- Tailored approach to our client’s needs

Hydraulic blocks solutions for all industries

VMF Hydraulics supplies hydraulic manifold blocks to all industries

Our skills as well as our plant capacity allow us to supply our clients with small, medium or large batches of either standard or bespoke hydraulic blocks. We are able to meet very specific demands linked to exceptional projects and manufacture single blocks.

Offshore (oil and gas)

Construction and Civils

Agricultural equipment

Windfarms

Arms industry

Marine sector

Materials and finishes :

meet all your demands

VMF Hydraulics offers a wide range of materials and finishes for manifold blocks.

Materials

From standard blocks to bespoke blocks, we offer a wide range of materials :

- Cast Iron

- Steel

- Aluminiums

- Stainless Steel

Different materials have different characteristics, this is why it is key to have a choice depending on the intended use. Aluminium is often recommended in mobile systems because of its light weight. Stainless steel, however, is recommended for saline environments in marine use.

Surface Treatment

We offer our clients several options for surface treatment depending on the intended use of the hydraulic block :

- Phosphating

- Chemical nickel

- Galvanising

- Hard and colour anodisation

All our manifold blocks undergo phosphating, unless a special treatment is needed. In saline environments, we recommend using chemical nickel to reinforce the resistance against rusting.

They trust us